Have a Rusty AC? Here Are the Common Causes and Solutions

Modern air conditioning systems are designed to endure significant wear and tear; however, Father Time eventually catches up with your air conditioning system, particularly if it's more than 15 years old and hasn't been adequately maintained.

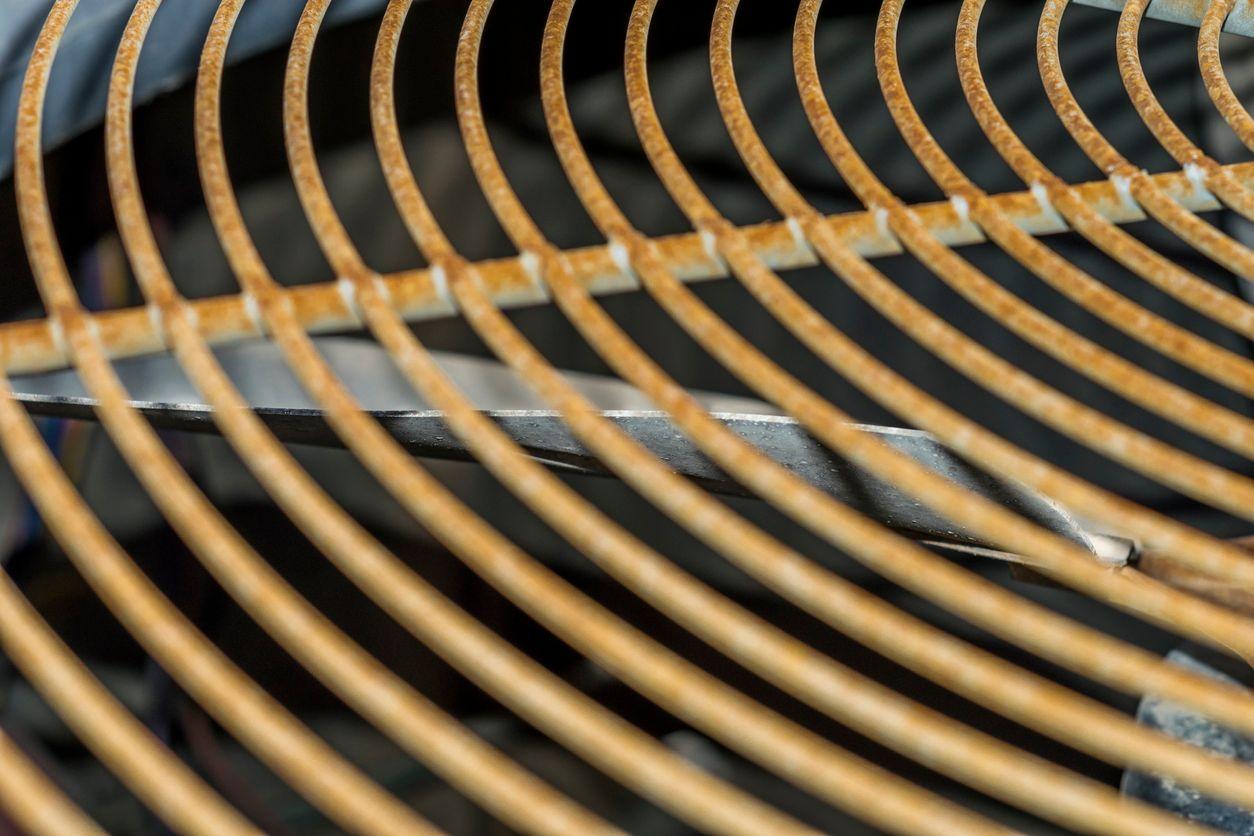

Aside from internal issues, air conditioners can also develop rust over time. If you own a rusty AC system, it's important to contact a trustworthy HVAC repair company to help you determine the best course of action. Although replacement is often a viable option, a repair is possible depending on the age of the system and the components affected. Keep reading to learn more about the causes and solutions for a rusty AC.

Common Causes of a Rusty Air Conditioner

- Outdoor Exposure. Exposure to high levels of moisture, humidity, sun, and other environmental elements can cause metal components to rust over time. Air conditioners near coastal areas are at a higher risk of rust due to salt in the air accelerating corrosion. Repeated exposure to a sprinkler system can also lead to rust.

- Age. Air conditioners are more prone to rusting when they're over 15 years of age, which is when AC replacement is typically recommended. Older units may have worn paint or protective coatings that make them more prone to rust.

- Poor Drainage. Inadequate drainage of condensation can lead to pooling water within the unit, promoting rust formation. “The most common cause of rust in an AC is too much moisture,” said Skylar Christensen, with Beehive Plumbing in Salt Lake City, UT. “If the drain is clogged, moisture can collect and cause rust to form.”

- Lack of Maintenance. Neglecting regular cleaning and maintenance allows dirt and debris to accumulate, trapping moisture and accelerating rust.

- Manufacturing Quality. Lower-quality materials or inadequate protective coatings during manufacturing can contribute to rust issues.

Solutions for a Rusty AC

If your air conditioner is rusted, a reputable HVAC technician should inspect the unit and help you determine whether AC repair or replacement is warranted.

Given rust forms over a long period of time, usually over a span of 10-15 years, it's worth considering replacing the entire system. Upgrading to a new, high-efficiency air conditioner will lower energy consumption, reduce the likelihood of sudden breakdowns, and prevent any additional rust issues.

If the compressor is badly rusted, AC replacement is often the best option. An AC compressor is responsible for circulating refrigerant and compressing it to facilitate the transfer of heat from inside a building to the outside, enabling the cooling process in an air conditioning system.

On average, AC compressor replacement costs between $500 and $1,500, while AC condenser replacement typically runs between $1,500 and $4,000, according to ThePricer.org. If the compressor is rusted and damaged and the unit is more than 10 years old, consider replacing the entire AC condenser unit.

However, if the unit is under 10 years old and the rust is contained to certain parts, a repair may suffice. Some rusted AC parts that can commonly be repaired or replaced include:

- Condenser coils

- Contactor terminals

- Wire terminals

- Brackets and screws

- Fins

- Motors

- Capacitors

- Fan blades

Rust can also be repaired on the condenser cabinet.

“In cases where rust has severely corroded components like the condenser coil or major structural elements, replacement is often the more practical solution,” said Nicholas Martin, director of marketing at Happy Hiller Plumbing, Heating, Cooling, and Electrical. “Attempting repairs on heavily rusted components may be cost-ineffective and could lead to recurrent issues. Minor rust on non-critical parts can sometimes be repaired with appropriate treatments.”

Regular Maintenance Can Prevent AC Rust

The best way to prevent AC rust from forming prematurely is through regular maintenance. Air conditioning maintenance should typically be performed in the spring, or before the arrival of warmer weather.

During an HVAC maintenance visit, a technician will carefully remove debris and dirt from the coils and fins using brushes and compressed air, followed by inspecting and cleaning the fan blades. Finally, they will address any rust or corrosion, lubricate moving parts, and ensure optimal airflow for improved cooling efficiency.

“Regular maintenance is key to preventing rust,” Martin said. “Keep the AC unit clean and free of debris, as accumulated dirt and organic matter can trap moisture and accelerate rust. Applying protective coatings, like anti-corrosion sprays, can create a barrier against moisture and environmental factors. Regular inspections by professionals can catch early signs of rust and address them promptly. By practicing proper maintenance, you can significantly delay the onset of rust-related problems, regardless of the age of the system.”